Item Per Page

6.3x50mm Batten Scre

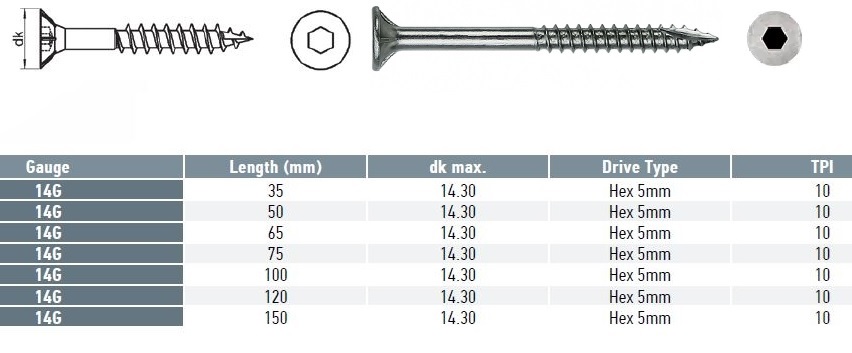

BUGLE BATTEN SCREW T17 A4 (316) 14G-10x50

6.3 x 65mm batten Sc

BUGLE BATTEN SCREW T17 A4 (316) 14G-10x65

6.3x75mm 316 Batten

BUGLE BATTEN SCREW T17 A4 (316) 14G-10x75

6.3x100mm Batten Scr

BUGLE BATTEN SCREW T17 A4 (316) 14G-10x100

6.3x120mm Batten Scr

BUGLE BATTEN SCREW T17 A4 (316) 14G-10x120

6.3x150mm Batten Scr

BUGLE BATTEN SCREW T17 A4 (316) 14G-10x150

Stainless Steel Batten Screws 316 Marine Grade

316BB14GX50

$ 0.76 each

- 1-9 Piece $ 0.76 each

- 10-99 Piece $ 0.55 each

- 100-249 Piece $ 0.39 each

- 250 onward $ 0.29 each

316BB14GX65

$ 0.95 each

- 1-9 Piece $ 0.95 each

- 10-99 Piece $ 0.70 each

- 100-499 Piece $ 0.55 each

- 500 onward $ 0.44 each

316BB14GX75

$ 1.06 each

- 1-9 Piece $ 1.06 each

- 10-99 Piece $ 0.78 each

- 100-999 Piece $ 0.70 each

- 1000 onward $ 0.50 each

316BB14GX100

$ 1.39 each

- 1-9 Piece $ 1.39 each

- 10-99 Piece $ 0.95 each

- 100-499 Piece $ 0.80 each

- 500 onward $ 0.70 each

316BB14GX120

$ 1.96 each

- 1-9 Piece $ 1.96 each

- 10-99 Piece $ 1.25 each

- 100-499 Piece $ 0.89 each

- 500 onward $ 0.82 each

316BB14GX150

$ 2.40 each

- 1-9 Piece $ 2.40 each

- 10-99 Piece $ 1.50 each

- 100-499 Piece $ 1.10 each

- 500 onward $ 0.90 each

Addon Products

Add0 Reviews

$

Quantity

Categories

Stainless Steel Batten Screws 316 Marine Grade

...

Grade 316 A4-70 Stainless Steel Bugle Batten Screws Diameter 14 Gauge=6.3mm thick

Marine grade 316 stainless steel batten screws offer several advantages over galvanized (gal) and 304 stainless steel screws, particularly in harsh environments. Here are the key benefits:

-

Superior Corrosion Resistance:

- 316 Stainless Steel: Contains molybdenum, which significantly enhances its resistance to corrosion, especially in chloride or saline environments. This makes it ideal for marine applications where exposure to saltwater is common.

- Galvanized Steel: Galvanized screws have a zinc coating that provides a level of corrosion resistance, but this coating can wear off over time, especially if scratched or damaged, leading to rust and corrosion.

- 304 Stainless Steel: Offers good corrosion resistance but is not as effective as 316 in highly corrosive environments, particularly those involving chlorides or saltwater.

-

Durability and Longevity:

- 316 Stainless Steel: Known for its high durability and ability to withstand harsh conditions without degrading. This longevity translates to fewer replacements and maintenance over time.

- Galvanized Steel: While initially resistant to rust, the protective zinc layer can deteriorate, reducing the lifespan of the screws.

- 304 Stainless Steel: Although durable, 304 screws may require more frequent replacements in corrosive environments compared to 316.

-

Aesthetic Appeal:

- 316 Stainless Steel: Maintains a clean, rust-free appearance even in harsh conditions, making it suitable for visible applications where aesthetics matter.

- Galvanized Steel: The zinc coating can dull over time, and any corrosion can lead to an unsightly appearance.

- 304 Stainless Steel: Generally retains its appearance well but can show signs of corrosion in more aggressive environments.

-

Strength and Reliability:

- 316 Stainless Steel: Provides high strength and reliability, ensuring secure fastening in critical applications such as marine, coastal, and industrial environments.

- Galvanized Steel: Strong but can be compromised if the coating is damaged, leading to potential failure.

- 304 Stainless Steel: Strong and reliable but not as corrosion-resistant as 316, which can affect its performance over time in certain conditions.

-

Resistance to Pitting and Crevice Corrosion:

- 316 Stainless Steel: Particularly resistant to pitting and crevice corrosion, which are common in marine environments where salt and other chemicals are present.

- Galvanized Steel: Susceptible to pitting and crevice corrosion once the zinc layer is compromised.

- 304 Stainless Steel: More prone to pitting and crevice corrosion compared to 316.

In summary, 316 stainless steel batten screws are the preferred choice for applications requiring high corrosion resistance, durability, and reliability, particularly in marine and other harsh environments. They offer a significant performance advantage over both galvanized and 304 stainless steel screws in these conditions.