Stainless Steel Batten Screws Grade 304

...

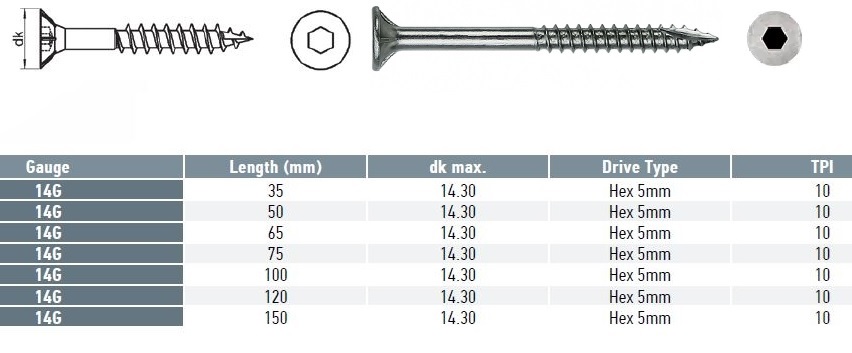

Stainless Steel Bugle Batten Screws Grade 304 14 Gauge = 6.3 mm

Grade 304 stainless steel batten screws offer a balance of benefits and drawbacks when compared to galvanized (gal) and 316 stainless steel screws. Here are the key advantages and disadvantages:

Advantages of Grade 304 Stainless Steel Batten Screws:

-

Cost-Effectiveness:

- 304 Stainless Steel: Typically less expensive than 316 stainless steel, making it a more cost-effective option for projects where extreme corrosion resistance is not necessary.

- Galvanized Steel: Generally cheaper than both 304 and 316 stainless steel, but this comes at the cost of lower corrosion resistance.

- 316 Stainless Steel: More expensive due to its higher molybdenum content and superior corrosion resistance.

-

Corrosion Resistance:

- 304 Stainless Steel: Provides good corrosion resistance, suitable for many outdoor and mildly corrosive environments.

- Galvanized Steel: Offers initial corrosion resistance due to the zinc coating but can corrode once the coating is damaged.

- 316 Stainless Steel: Offers superior corrosion resistance, especially in marine and chloride-rich environments.

-

Strength and Durability:

- 304 Stainless Steel: Strong and durable, suitable for many structural applications.

- Galvanized Steel: Strong but can weaken if the zinc coating is compromised.

- 316 Stainless Steel: Stronger and more durable than 304, particularly in corrosive environments.

-

Aesthetic Appeal:

- 304 Stainless Steel: Maintains a clean, attractive appearance, making it suitable for visible applications.

- Galvanized Steel: The zinc coating can dull over time, and corrosion can lead to an unsightly appearance.

- 316 Stainless Steel: Retains a clean, rust-free appearance even in harsh conditions.

-

Availability:

- 304 Stainless Steel: Widely available and easy to source for a variety of applications.

- Galvanized Steel: Also widely available and easy to find.

- 316 Stainless Steel: Less readily available than 304 and more specialized.

Disadvantages of Grade 304 Stainless Steel Batten Screws:

-

Corrosion Resistance in Harsh Environments:

- 304 Stainless Steel: Not as resistant to chloride and saltwater corrosion as 316 stainless steel, making it less suitable for marine environments.

- Galvanized Steel: Inferior to both 304 and 316 in terms of long-term corrosion resistance.

- 316 Stainless Steel: Superior corrosion resistance, especially in marine and harsh industrial environments.

-

Cost:

- 304 Stainless Steel: More expensive than galvanized steel, though cheaper than 316.

- Galvanized Steel: Most cost-effective option for applications with less demanding corrosion resistance requirements.

- 316 Stainless Steel: Most expensive option due to higher corrosion resistance.

-

Pitting and Crevice Corrosion:

- 304 Stainless Steel: More susceptible to pitting and crevice corrosion in chloride-rich environments compared to 316.

- Galvanized Steel: Can experience corrosion once the zinc layer is breached.

- 316 Stainless Steel: Highly resistant to pitting and crevice corrosion.

-

Specialized Applications:

- 304 Stainless Steel: May not be suitable for highly specialized applications requiring maximum corrosion resistance.

- Galvanized Steel: Limited by the protective coating's durability.

- 316 Stainless Steel: Preferred for specialized applications requiring extreme corrosion resistance.

Summary

- Grade 304 stainless steel batten screws are a good middle-ground option, offering a balance of cost, availability, and corrosion resistance for many applications. However, they are not the best choice for environments with high levels of chlorides or where maximum corrosion resistance is crucial.

- Galvanized screws are cost-effective but less durable in terms of corrosion resistance.

- Grade 316 stainless steel screws provide the best corrosion resistance and durability but at a higher cost, making them ideal for harsh and marine environments.